I. Introduction:

ZB1000A6 is specialized in packing products into vacuum status and brick shapes, various kinds of powder or granules are available, such as coffee,

yeast, tea leaves etc. It’s best to work with vertical form fill and seal machines to complete the automatic bagging line, Which consisting of screw

loading conveyor with vibratory hopper feeder, auger filler dosing system, automatic bag making machine with date printing unit, and the vacuum

brick maker. Packed bag keep high quality in sealing, long time in reserving, smart in outlook.Advanced in vibration, pressing, reforming, vacuuming,

sealing, cutting, smoothing and conveying such chief processing step, take result in getting nice bag shape and appropriate vacuum degree.

II.Advantages:

|

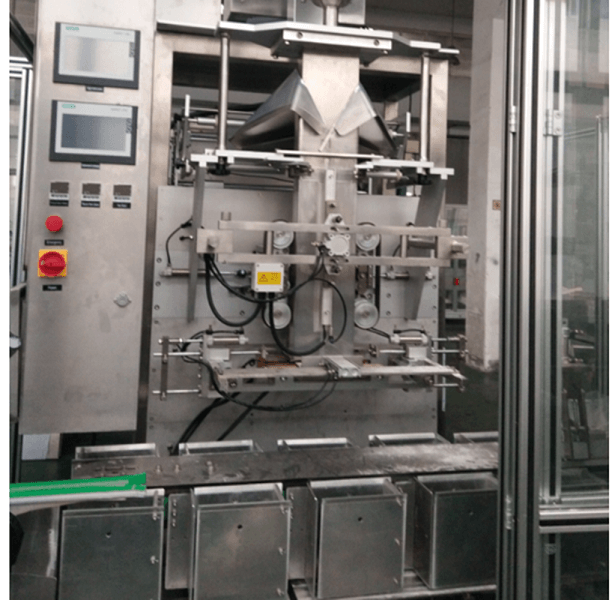

VFS5000F packaging machine |

CJS2000 Weighing machine |

|

Machine fully controlled by Siemens or Omron PLC & Touch-Screen |

|

|

Minute capacity can automaticlly display on Touch screen |

Can be detached for easy clean |

|

Film transport system and horizontal Jaw motion both drive by Panasonic |

Simple and compact in design |

|

Safe quick change of tube and collar by just pull out the braket. |

All stainless steel product contact parts. Non-contact parts are stainless steel and aluminum |

|

Optoelectronics detect film position on collar to correct film excursion |

|

|

Electrical photo sensor inducting color code to control bag length |

|

|

Unique Pneumatic Film-Reel locking structure to avoid film drawing deflecting |

|

|

Independent temperature adjustment. |

|

|

Various types of heating sealable laminated films namely PE/BOPP, CPP/BOPP, CPP/PET, PE/NYLON, aluminum foil based can be run on the machine. |

|

|

The packaging machine also can be used for Polyethylene Film Sealing by changing correspond equipment. |

|

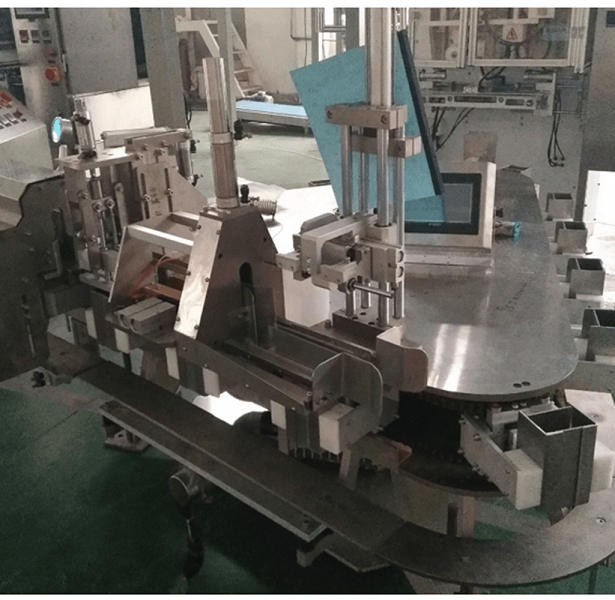

ZB1000 Vacuum &bag reshape system |

|

Auto Vibrate, Form, Vacuum & Reseal Brick Bag |

|

Stable working with SIEMENS PLC,Panasonic Servo Drive, |

III. Technical Parameters:

|

Bag type |

Vacuum & Reseal Brick Bag |

|

|

Maximum Capacity |

up to 2.5 kilograms |

|

|

Minimum Capacity |

0.5kg |

|

|

Speed |

8-20 times/min |

|

|

Hopper capacity |

50Litres |

|

|

Weighing accuracy |

±0.2% dependant on products characteristics |

|

|

Bag Length |

50 to 340mm (2.0 to 13.4in) |

|

|

Bag Width |

80 to 260mm (3.1 to 10.3in) |

|

|

Reel Film Width |

≤540mm (21.2in) |

|

|

Film thickness |

0.04-0.12mm (40-120mic.) |

|

|

Reel Outer Dia. |

400mm (15.7in) |

|

|

Reel Inner Dia. |

75mm (2.9in) |

|

|

Voltage |

AC380V/50-60Hz, 3phase |

|

|

Power Consumption |

VFS5000F packaging machine |

3KW |

|

CJS2000 Weighing machine |

0.5kw |

|

|

ZB1000 Vacuum &bag reshape system |

5.5KW |

|

|

Compressed Air Requirement |

0.6 MPa0.36 M3min |

|

|

Machine Size |

VFS5000F packaging machine |

L1650 x W1140 x H1650; (in):L65.1 X W44.9 X H64.9 |

|

CJS2000 weighing machine |

L940*W700*H1580 |

|

1.The packing machines will be wrapping by film firstly and then packed in export standard plywood wooden cases;

2.We can delivery machines by sea,train,air,etc. According to customer's requirement;

3.We will delivery machine from any sea port in China

|

Efficient Service |

|

|

Documents |

English version manual book and wires connecting drawing will be give at the time of dispatch of machine, we will also offer the documents for custom to clean custom. |

|

Guarantee |

The machine is guaranteed for trouble free performance for a period of 12 months from commissioning. |

|

Service |

We can arrange and send engineer abroad for helping customer install and test and learn the machines, we also send necessary spare parts in first time. |

Hefei Vactec Packaging Technology Co., Ltd is located in the famous science and education city-Hefei. Our company is a high-tech company specialized in the R&D, production ,sales and after-sales service automatic packing machines and relative auxiliary equipments in China.

Vactec sets up six professional divisions: vertical packaging machinery, bag-feeding packaging machine, automatic weighing machine, vacuum packaging machine, inspection machinery and filling machinery. The machines are widely used in chemical, building materil, food ,beverage, beer and automatic logistic industries.

Through these years development, Vactec various technology are improving daily. Especially the technology of heavy bag packaging machine and secondary packaging machine is the domestic original technology, its products stay at the world leading level and has signed global purchase strategic plan with several world top 500 enterprises, has provided nearly one hundred sets of packaging solutions and its products are used in various sectors. Its typical customers are: Unilever (OMO), P & G, Charoen Pokphand Group, Liby Group, Industrias Alimenticias Gustossi Srl Group, UCI Indonesia salt company, Yihai Grain and Oil, COFCO, Dongfang Yuhong Technology Co., Ltd., Taetee Group, Sinopec Baling Branch, Zhengzhou Sanquan Foods, Shuanghui Co., Ltd., etc.

Contact Us!

Contact Us!