I. Introduction:

This unit is for granule products automatic material weighing & Filling,bagging, date coding for Preformed Pouches etc.

Including bellowing machines:

1)Bucket elevator for Material feeding ;

Elevating height: 4 meter

Capacity: 3-6CBM/hour

Material of bucket: ABS food grade plastic

Motor power: 1.1kw 380v with Photo electricity

Machine-material: Stainless,steel, plastic

2)CJSL2000 auger filler;

Application:

CJSL2000 auger filler can be used semi-automatic for filling powder in bags, bottles, jars and boxes. Also it can be work with the VFS series vertical packaging machine to realize automatic powder material weighing ,filling and packaging

Advantage:

|

·Servo motor control auger filling |

|

·With full colour Touch Screen for better operating of the machine |

|

·Can be detached for easy clean |

|

·Simple and compact in design |

|

·All stainless steel product contact parts. Non-contact parts are stainless steel and aluminum. |

3)Supporting platform with guardrail & Ladder;

Made by carbon steel or stainless steel, with guardrail and ladder

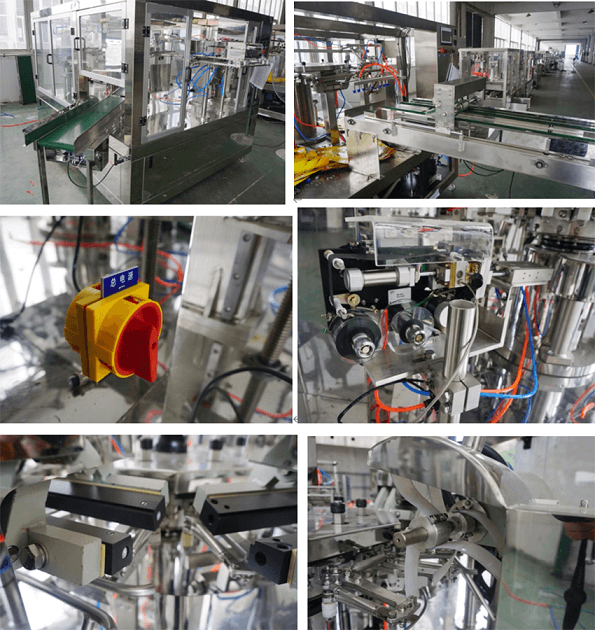

4)ZR series Rotary bagging machine;

Function and characteristics

1 、Easy to operate,adopt advanced PLC from Germany Siemens, mate with touch screen and electric control system, the man-machine interface is friendly.

2 、Frequency conversion adjusts the speed: this machine uses frequency conversion equipment, can be adjusted within the range according to the needs of reality in production

3、Automatic checking: no pouch or pouch open error, no fill, no seal. the bag can be used again, avoid wasting packing materials and raw materials.

4 、Safety device: Machine stop at abnormal air pressure, heater disconnection alarm。

5 、Horizontal conveyer style to giving bag: it can put on more bags on the bag storage and have a low requirement about the quality of bags.

6 、 The width of the bags could be adjusted by electrical motor. Press the control-button could adjust the width of clips, easily operate, and save time.

7 、It match with the glass safety door. At the same time, it could prevent dust.

8 、Use the plastic bearing, don’t need put on oil, less pollution.

9 、Use no oil vacuum pump, avoid polluting the environment in the production.

10、. The opening zipper framework is special in the feature of zipper bag,it can avoid distortion or destroy when open the zipper

11、The packing materials loss low, what this machine is used the preformed bag, the bag pattern is perfect and has a high quality of the sealing part, this improved the product specification

12、Product or packing bag contact parts adopt stainless steel or other materials which accord with the food hygienic requirements, guarantee hygiene and security of the food

13、With different feeders changed to pack solid, liquid, thick liquid ,powder and so on.The packing bag suits in extensive range, suit for multi-layer compound, monolayer PE , PP and so on Preformed bag made by film and paper.

5)Take off conveyor belt.

II. Application:

III.Technical information:

|

Model |

Weigher/Filler/Dosing system |

Working station |

Bag type |

Bag size:(mm) |

Packaging speed |

|

ZR8-200 |

GZ1000 |

8 |

Pillow bag, 4 side/ 3 side seal bag, Stand up bag with Zipper; |

W(80-200)*L(100-300) |

Max 50BPM |

|

ZR8-260 |

GZ1000 |

8 |

W(130-260)*L(100-300) |

Max 50BPM |

|

|

ZR8-300 |

GZ2000 |

8 |

W(180-300)*L(200-500) |

Max 40BPM |

Note:GZ1000/GZ2000: Rotary pump/Piston Pump Filler

1.The packing machines will be wrapping by film firstly and then packed in export standard plywood wooden cases;

2.We can delivery machines by sea,train,air,etc. According to customer's requirement;

3.We will delivery machine from any sea port in China

|

Efficient Service |

|

|

Documents |

English version manual book and wires connecting drawing will be give at the time of dispatch of machine, we will also offer the documents for custom to clean custom. |

|

Guarantee |

The machine is guaranteed for trouble free performance for a period of 12 months from commissioning. |

|

Service |

We can arrange and send engineer abroad for helping customer install and test and learn the machines, we also send necessary spare parts in first time. |

Hefei Vactec Packaging Technology Co., Ltd is located in the famous science and education city-Hefei. Our company is a high-tech company specialized in the R&D, production ,sales and after-sales service automatic packing machines and relative auxiliary equipments in China.

Vactec sets up six professional divisions: vertical packaging machinery, bag-feeding packaging machine, automatic weighing machine, vacuum packaging machine, inspection machinery and filling machinery. The machines are widely used in chemical, building material, food ,beverage, beer and automatic logistic industries.

Contact Us!

Contact Us!